Description

PLEASE BE AWARE – All our swords and replicas are intended for ornamental display or historical interest only. Nothing we sell is recommended or suitable for combat and such use is strictly prohibited.

"Second World War Officers Katana" Handmade Katana in 1095 Clay Tempered Blade with Kobuse Lamination.

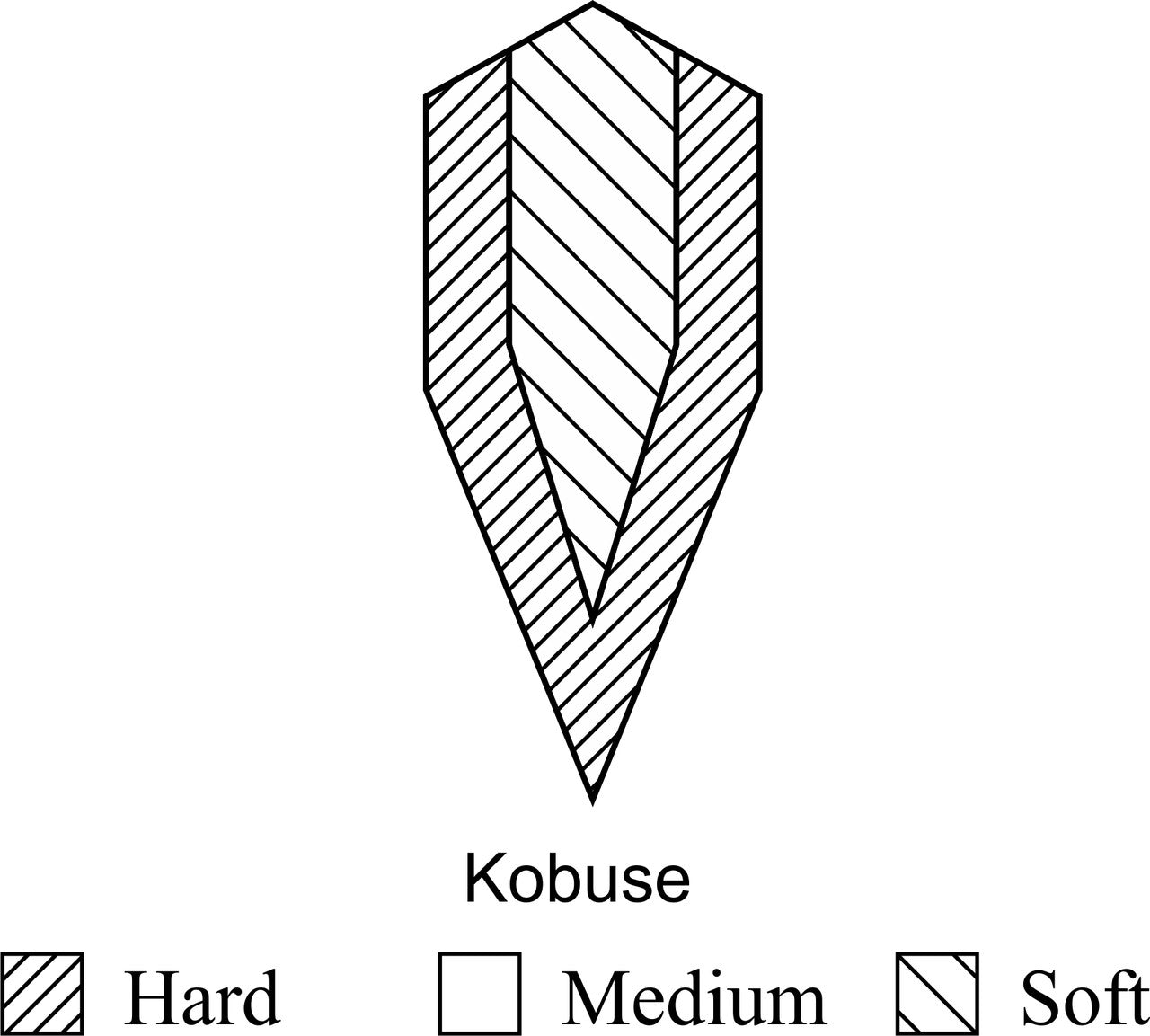

The successful combination of the lamination or folding technique and the differential heat treatment technique, along with the skill and experience to do the job properly, are the true art of making a masterpiece Katana. In this Katana the smith has selected Kobuse lamination as the lamination technique and clay tempering as the differential heat treatment tempering process.

The blade is laminated using the ‘Kobuse’ lamination process. Kobuse lamination involves laminating 2 types of metal to offer a hard brittle crust that is razor sharp and can keep the edge, but leave the core of the blade more soft and durable and able to absorb impact and avoid shattering.

The purpose of the clay tempering process is to further improve the sharpness of the edge and durability of the overall blade. It involves smearing clay on the blade during heating and quenching to offer a uniform hardness to the blade and remove weak points which can occur when the heating or quenching is less even. It also allows the smith, by placing the clay thicker on certain parts of the blade, to make the edge harder (thus more able to keep the famous razor sharp samurai edge) and the rest of the blade less hard but more able to absorb impact.

The wooden handle is wrapped in genuine Stingray skin (Samekawa) before the traditional cotton handle wrapping (Tsukamaki). The saya (sheath) fittings are of faux mother of pearl. The sageo (or ‘ito’) – which is the material wrapped around the saya – is made of cotton. The wooden box, black sleeve, cleaning kit and stand are included. The hamon on this sword is real. There is no bohi (groove in the blade for weight reduction).

Over 18s only. Please be aware, if you are a new customer we will need to see age verification before sending your order. This is not necessary for returning/registered customers. Please send us a photo of relevant ID (such as Driving Licence or Passport showing Date of Birth) at time of purchase by email to help@theswordstall.co.uk or WhatsApp 07932 932801.

Under UK law, curved swords over 50cm in length are illegal unless they are antique or traditionally hand forged. All of our curved katana are certified as being traditionally hand forged. Display Katana are straight bladed and blunt and as such are legal to own in the UK.

Overall Length (cm) 106

Blade Length (cm) 73

Handle Length (cm) 29

Blade Width (cm) 3.2

Blade Thickness (cm) 0.75

Blade Material Clay-tempered Kobuse 1095

Blade Hardness HRC 58

Saya Material Hard Wood

Tsuba Material Iron

Fittings Material Iron

Sageo Material Cotton

Over 18s only. Please be aware, if you are a new customer we will need to see age verification before sending your order. This is not necessary for returning/registered customers. Please send us a photo of relevant ID (such as Driving Licence or Passport showing Date of Birth) at time of purchase by email to help@theswordstall.co.uk or WhatsApp 07932 932801.

Under UK law, curved swords over 50cm in length are illegal unless they are antique or traditionally hand forged. All of our curved katana are certified as being traditionally hand forged. Display Katana are straight bladed and blunt and as such are legal to own in the UK.