The Katana, a symbol of the samurai’s honor and craftsmanship, is one of the most revered weapons in Japanese culture. Hand-forging a Katana is not just a process of creating a sword; it’s a meticulous art form passed down through generations of master swordsmiths. In this blog, we’ll explore the traditional steps involved in crafting a Katana by hand, revealing the incredible skill and dedication required to produce this iconic weapon.

The History and Significance of the Katana

The Katana’s origins date back to feudal Japan, where it became the weapon of choice for samurai warriors. Known for its curved, slender, and razor-sharp blade, the Katana was more than just a tool for battle—it was a reflection of the warrior’s soul. Swordsmiths who crafted these blades were highly respected, as their work was seen as both a craft and a sacred duty.

In Japanese culture, the Katana Sword is a symbol of justice, honor, and protection. The sword’s creation is steeped in ritual, with each step of the forging process designed to imbue the blade with strength, resilience, and a spirit that mirrors the samurai who wields it.

Materials Needed for Forging a Katana

Forging a Katana requires specific materials, each chosen for its role in creating the sword’s distinctive qualities:

- Tamahagane: Traditional Japanese steel made from iron sand, known for its high carbon content and purity.

- Clay: Applied during the differential hardening process to control the cooling rate of the blade.

- Water: Used for quenching the blade to harden the steel.

- Charcoal: Provides the heat needed for forging and shaping the steel.

Each material plays a crucial role in the forging process, contributing to the Hand Forged Katanas unique combination of hardness, flexibility, and sharpness.

The Traditional Katana Forging Process

Step 1: Smelting and Preparing the Steel

The process begins with creating tamahagane, a type of high-quality steel. This is done by smelting iron sand in a tatara furnace, a traditional Japanese furnace that reaches extremely high temperatures. The iron sand is melted with charcoal to produce steel, which is then broken into pieces, sorted by carbon content, and selected for further processing.

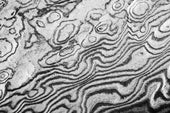

Step 2: Folding the Steel

To create the Katana’s distinct layers, the steel is repeatedly heated, hammered, and folded. This folding process can be repeated up to 15 times, resulting in thousands of layers. Folding the steel helps to remove impurities and evenly distribute carbon, enhancing the blade’s strength and flexibility.

Step 3: Forming the Blade of the Katana

Once the steel is ready, it’s time to shape the blade. The swordsmith heats the steel and hammers it into the basic shape of the Katana. Traditional tools like hammers, anvils, and chisels are used to refine the blade’s curvature and profile.

Step 4: Differential Hardening

One of the most critical steps in Katana forging is differential hardening. The swordsmith applies a layer of clay to the blade, with a thicker layer along the spine and a thinner layer along the edge. The blade is then heated and quenched in water. This process hardens the edge while keeping the spine softer, giving the Katana its characteristic curved shape and creating the hamon, or temper line, that is unique to each sword.

Step 5: Polishing and Sharpening the Katana

After hardening, the blade undergoes a meticulous polishing process. Sword polishers use a series of progressively finer stones to sharpen the edge and reveal the hamon. This process can take several days and is crucial for bringing out the Katana’s beauty and sharpness.

Step 6: Assembling the Katana

With the blade complete, the swordsmith then crafts the tsuka (handle), tsuba (guard), and saya (scabbard). These components are often intricately decorated and personalized. The handle is wrapped in ray skin and silk, providing a secure grip, while the tsuba protects the hand and adds to the sword’s aesthetic appeal. Finally, the blade is fitted into the scabbard, completing the Katana.

The Role of the Swordsmith

Forging a Katana is not just about technique; it’s about the swordsmith’s mastery and artistry. A skilled swordsmith dedicates years, often decades, to perfecting their craft. The quality of the Katana depends on the swordsmith’s ability to balance tradition with precision, ensuring that each blade is a work of art as well as a deadly weapon.

In Japan, swordsmithing is a revered profession, with many swordsmiths belonging to families that have passed down the craft for generations. This lineage is part of what makes each Katana unique, as the sword carries the legacy of its maker.

Modern vs. Traditional Katana Forging

While modern technology has introduced new methods and materials for sword-making, traditional Katana forging remains highly respected and sought after. Modern techniques may use industrial steel and power tools, speeding up the process, but they often lack the soul and craftsmanship that define a traditionally forged Katana.

Collectors, martial artists, and enthusiasts continue to value Katanas made through traditional methods, not only for their superior quality but also for the cultural and historical significance they carry.